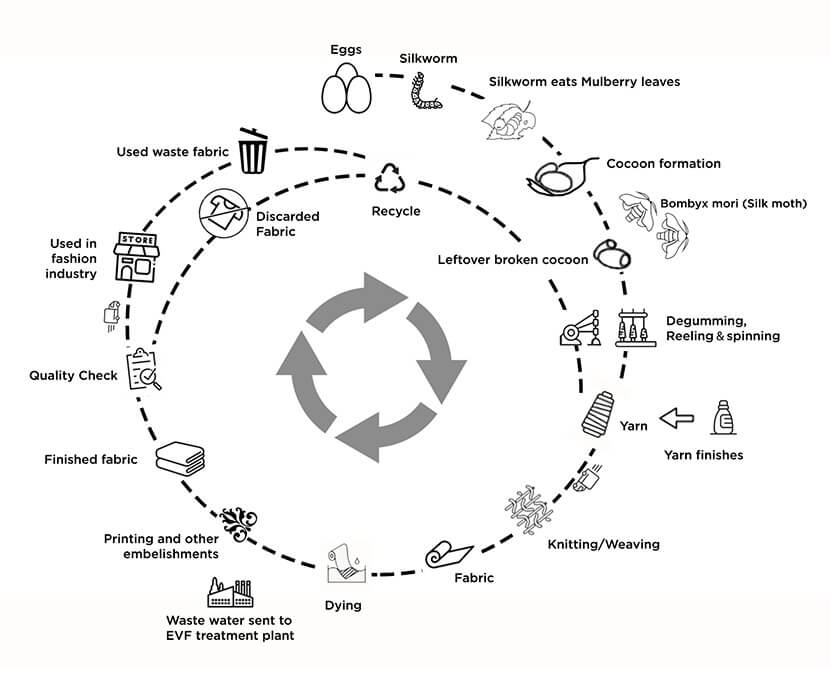

However, complex the image seem, the concept of circularity in fashion is fairly simple. It is the suggested life cycle of a fashion item that leads to almost zero waste.

Journey of silk starts with the silkworm. A silkworm created a cocoon of silk at the onset of its metamorphosis and comes out with wings as a silk-moth. The cocoon left behind is then used to extract silk by reeling and spinning. So essentially, silk is being made out of the waste left behind by the silk moth. This is unlike industrial silk where silkworms are killed inside the cocoon to obtained untethered silk fibers. On the other hand, we don't even let the dropping (excreta) of silkworms go to waste.

It serves as a great natural compost. Silkworms manure is one of the best alternatives for chemical fertilizers. Natural remedy solution has been prepared by blending plants with medicinal properties such as Guizotia abyssinica (ramtilla), Azadirachta indica (neem), Brassica juncea (India mustard). This unique blend displays 90% of similar outcomes as the chemical fungicides and pesticides yet without any toxic side effects towards the ecosystem.

We also use a solar powered water pumping system.

Later while reeling out silk from cocoon, solar powered water boilers are used. Hygiene is maintained but no chemicals are used. After monsoon, limited use is calcium hydroxide is done for disinfection. This has no side effect on ecology. For the degumming process, alkaline is used for balancing PH factor but no bleaching agents are used. Wastewater is treated in ETP plants and not exposed to ground. Hydrogen peroxide is used as a bleaching cum cleaning agent, which is water based and GOTS and REACH approved.

The silk obtained is then taken for weaving and the fabric obtained is sold for making designer garment. After the dress is sold, customers may use it however they like. Whenever they wish to discard the dress, they can bring it back to us. On each return, we give the customer discount vouchers that they can redeem right on their next purchase. With this incentive, we aim to get most of our products back after use and then recycle them. The fibres are extracted from it and again used to make few new garments and more.

Hence, at each and every step we try to reduce, reuse and recycle. Waste from one step, becomes resource for another step. This way zero waste can be achieved.